R & D

STERILE FORMULATIONS

PRE-FORMULATION AND FORMULATION DEVELOPMENT

PRE-FORMULATION AND FORMULATION DEVELOPMENT

Liquid and lyophilized formulations are developed in Gulf Biotech R&D unit. Our experts at R&D unit primarily focus on solubility, stability of the molecule as parenteral formulation and many other interrelated parameters which are required to develop sterile formulations. after successful product development, the process are validates and transferred to concern department for prototype small scale production.

STERILE LIQUID FORMULATION DEVELOPMENT

In addition to the standard product development procedure, our expert conduct the stability tests of newly develop product. along with other complex mathematics, Arrhenius models are used predict drug formulation shelf life. Other processes, compounding, complete process development, products filtration sterilization techniques, autoclave sterilization methods with defined standards and stability of finished product are the main process and procedures developed at R&D unit of Gulf Biotech.

In addition to the standard product development procedure, our expert conduct the stability tests of newly develop product. along with other complex mathematics, Arrhenius models are used predict drug formulation shelf life. Other processes, compounding, complete process development, products filtration sterilization techniques, autoclave sterilization methods with defined standards and stability of finished product are the main process and procedures developed at R&D unit of Gulf Biotech.

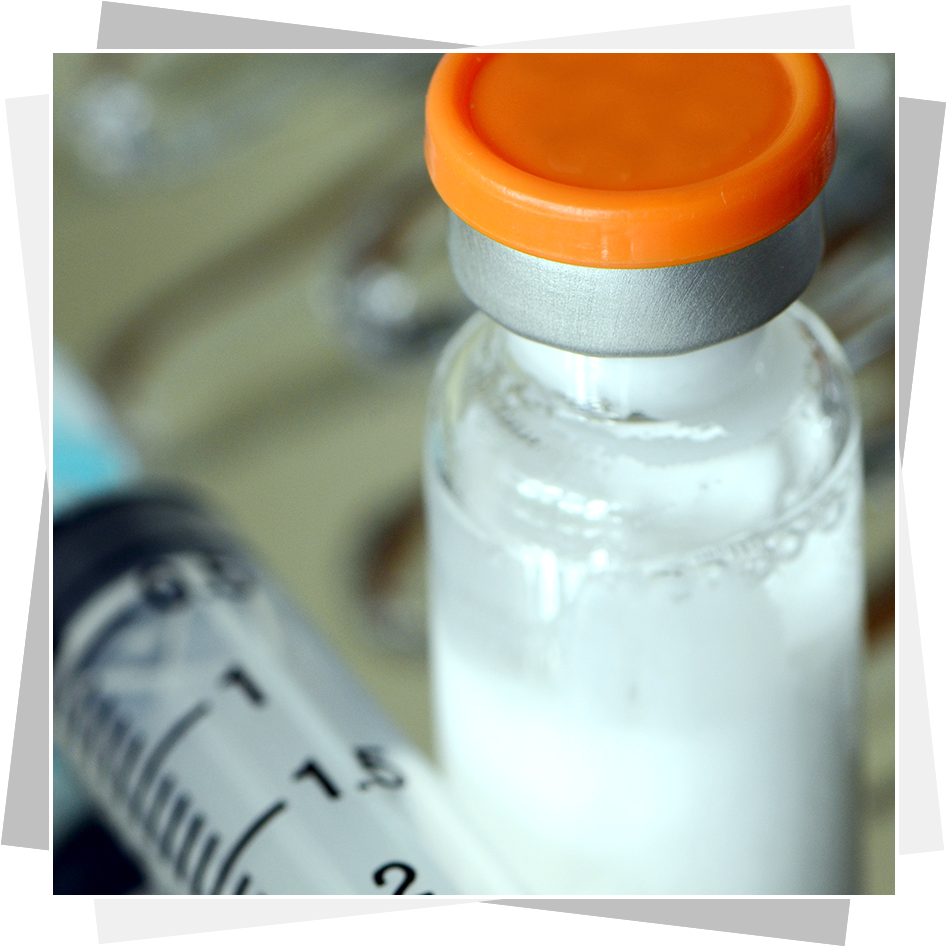

LYOPHILIZED FORMULATION DEVELOPMENT

The formulation development for Lyophilized products requires high level of skills and accuracy especially thermal stability related properties of the APIs and excipients. Our experts use advance techniques of freeze drying microscopy and differential scanning colorimetric and other related technologies. for the development of Lyophilization cycle, Lyophilization excipients are carefully selected. Experts at Gulf Biotech R&D unit optimize the Lyophilization cycle parameters, confirm the stability of Lyophilized compound and reconstituted solution. Finally, finished product stability is check under different conditions of temperature and humidity.

The formulation development for Lyophilized products requires high level of skills and accuracy especially thermal stability related properties of the APIs and excipients. Our experts use advance techniques of freeze drying microscopy and differential scanning colorimetric and other related technologies. for the development of Lyophilization cycle, Lyophilization excipients are carefully selected. Experts at Gulf Biotech R&D unit optimize the Lyophilization cycle parameters, confirm the stability of Lyophilized compound and reconstituted solution. Finally, finished product stability is check under different conditions of temperature and humidity.