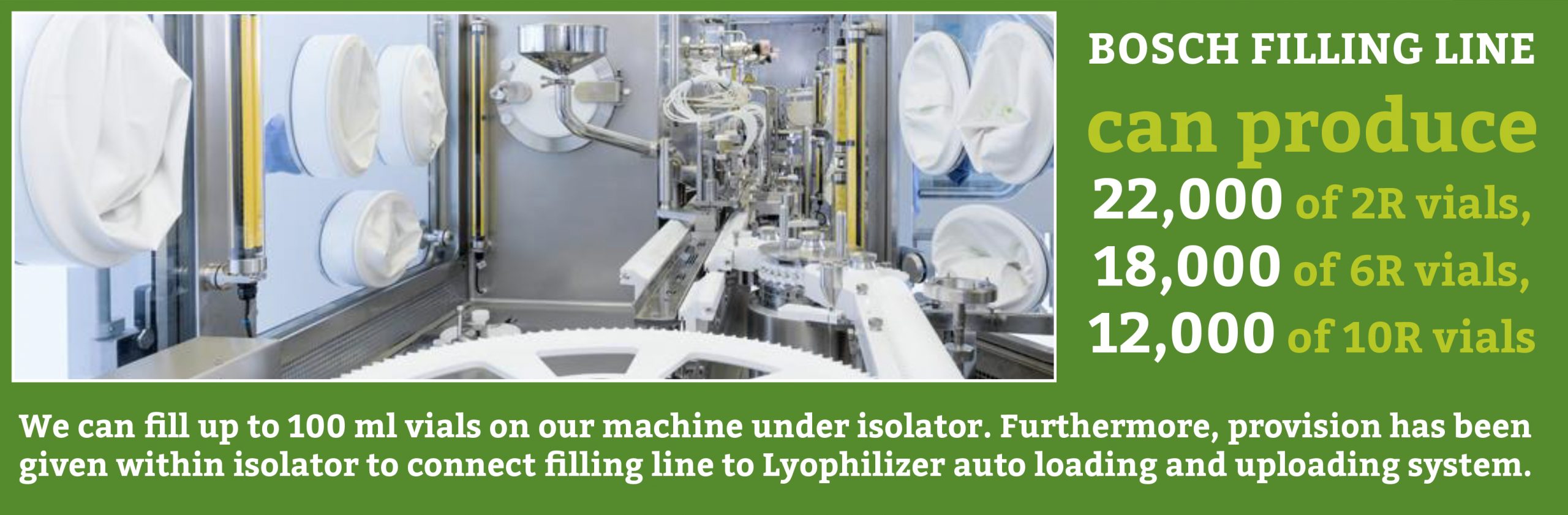

MEDICINE FILLING SYSTEM

BOSCH FILLING LINE INTRODUCTION

(COUNTRY OF ORIGIN: GERMANY)

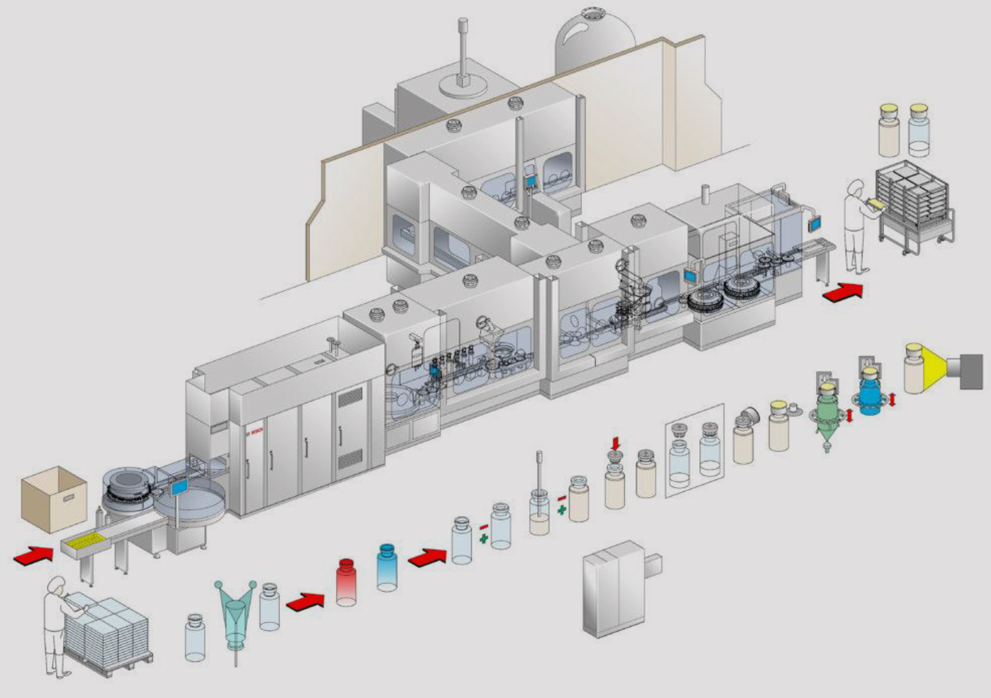

Bosch Vials Filling machine with isolators is designed to enclose the filling, stoppering and capping operations of a Liquid Filling Machine while providing an aseptic environment for the process, achieving ISO 5 grade A classification. This isolator allows for the entry of pre-sterilized stoppers and caps through a Rapid Transfer Port (RTP). APIs & other raw materials are also presented into the Isolator via the RTP. Glassware is transferred to the isolator in separate transfer isolators. The Transfer Isolator “docks” to the filling isolator via a RTP and the trays of glassware are manually positioned on the accumulator of the filling machine. The vials are automatically moved by the filling machine through the filling, stoppering and capping stations and exit through a “mouse hole” in the end wall of the isolator. A conveyor carries the vials from the Isolator under an external unidirectional airflow module and into the adjoining packaging room.

ADVANTAGES

- Ergonomically designed oval glove ports

- 316L stainless steel construction

- PLC control

- Positive pressure airflow system with HEPA filtration and a self-contained unidirectional airflow system

- Special “mouse hole” protected by unidirectional airflow for exit of filled vials

- Integrated Hydrogen Peroxide decontamination

- Temperature control to maintain the Isolator at ambient temperature with high/low set points.

COMPACT HYGIENIC DESIGN

MAXIMUM FLEXIBILITY

Flexible production without compromising user safety is a key requirement. The possibility to separate each of the four isolator segments (filling machine, lyophilizer loading and unloading, capping) enables Gulf Biotech to undertake different production steps on the same line at the same time. The line comprises an optimized H2O2 decontamination cycle thanks to the Bosch SafeVAP system in combination with dedicated catalytic H2O2 converters and adapted injection points. These modifications reduce decontamination time and production downtime.